Coriolis flow meters

Deliver unmatched reliability for your mass flow, volume flow & density measurement needs.

Coriolis flow meters

Deliver unmatched reliability for your mass flow, volume flow & density measurement needs.

Emerson’s Micro Motion Coriolis meters offer precise mass flow and density measurement through a combination of a sensor (with measurement tubes) and a transmitter (for displaying and configuring outputs). The product line includes various sensors, transmitters, and software options designed to meet diverse application needs, providing a comprehensive and reliable solution for critical flow measurement processes

A Coriolis meter measures mass flow using motion mechanics. The fluid entering the sensor is divided into two vibrating tubes. A drive coil makes the tubes oscillate in opposite directions at their natural frequency. As the tubes vibrate, sensors produce sine wave signals, and the time delay between the two waves, known as Delta-T, is directly proportional to the mass flow rate.

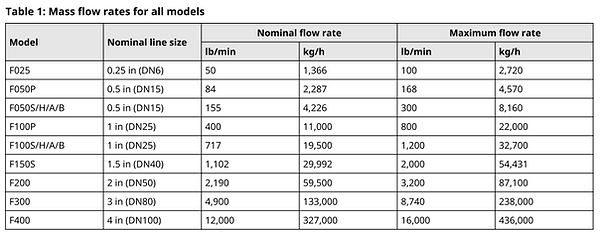

Range - Coriolis flow meters are widely used across many industries for accurate flow measurement. They come in various sizes and can measure flow rates from a few grams per hour up to about 54,431 kgs/min. Their linear signal provides a wide and dynamic measurement range.

F - Series - Flow and Density Meters

-

Best-in-class performance on liquid mass flow, volume flow, and density measurements in a compact design.

-

Rugged design minimizing process, mounting, and environmental effects

-

Cleanable, self-draining design for critical process control service

-

Compact design enables installation flexibility

-

No moving parts to wear or replace minimizes maintenance for long-term reliability

-

316L stainless steel and nickel alloy C22 wetted parts construction for compatibility with most fluids

-

Robust sensor design

Micro Motion™ F150S Coriolis Meter Features

-

A 316L Stainless Steel, Coriolis flow meter that delivers highly reliable, repeatable and robust measurement.

-

Achieve highly accurate mass volume flow and density measurement in applications that require a compact, drainable design

-

Improve measurement and tracking with extensive process and meter diagnostics with on-board historian and logging

-

Realize the fastest response rates and accurate batch and process measurement with unmatched MVD transmitter technology

-

Gain real-time and in-process measurement integrity assurance with Smart Meter Verification

Optimal flow and density fit for critical process applications

-

High performance rugged measurement in a compact drainable design that maximizes process up time

-

Low frequency, high sensitivity fit-and-forget meter provides robust measurements even under demanding process conditions

-

Multiple line sizes provide an ideal platform for batching, distribution, allocation, and intra-plant measurement applications

Smart Meter Verification™: advanced diagnostics for your entire system

-

Ordered as standard with the option to license flow range detection and other advanced meter health diagnostics.

-

Runs comprehensive tests that can be scheduled, run locally, or from the control room to provide confidence in your meter functionality and performance.

-

Verifies that your meter performs as well as the day it was installed, giving you assurance in less than 90 seconds.

-

Saves significant expenditure by reducing labor and extending or eliminating calibration intervals without interrupting the process

Industry-leading capabilities that unleash your process potential

-

Available with the most extensive offering of transmitter and mounting options for maximum compatibility with your system.

-

State of the art, ISO/IEC 17025 compliant calibration stands achieving ±0.014 percent uncertainty drive best in class measurement accuracy.

-

The most comprehensive communication protocol offering in the industry including Smart Wireless

Widest range of installation and process condition flexibility

-

Featuring a low pressure drop, low weight design that reduces installation and commissioning costs

-

Unmatched MVD™ transmitter technology with digital signal processing (DSP) delivers the fastest response rates, enabling accurate batch and process measurement.

-

Design flexibility enables operation at high temperature up to 662 °F (350 °C) or high pressure up to 6,237 psig (430 barg) to solve your toughest measurement challenges.

Measurement Principles

-

The Coriolis mass flow meter works by vibrating the flow tube that carries the fluid. This vibration creates a rotating reference frame that produces the Coriolis effect. Sensors detect changes in the tube’s frequency, phase shift, and amplitude, and these variations are used to determine the fluid’s mass flow rate and density.

Mass and volume flow measurement

-

The measuring tubes are forced to oscillate producing a sine wave. At zero flow, the two tubes vibrate in phase with each other. When flow is introduced, the Coriolis forces cause the tubes to twist resulting in a phase shift. The time

difference between the waves is measured and is directly proportional to the mass flow rate. Volume flow rate is calculated from mass flow rate and the density measurement.

Temperature measurement

-

Temperature is a measured variable that is available as an output. The temperature is also used internally in the sensor

to compensate for temperature influences on Young’s Modulus of Elasticity.

Micro Motion™ F150S Coriolis Meter Features

-

A 316L Stainless Steel, Coriolis flow meter that delivers highly reliable, repeatable and robust measurement.

-

Achieve highly accurate mass volume flow and density measurement in applications that require a compact, drainable design

-

Improve measurement and tracking with extensive process and meter diagnostics with on-board historian and logging

-

Realize the fastest response rates and accurate batch and process measurement with unmatched MVD transmitter technology

-

Gain real-time and in-process measurement integrity assurance with Smart Meter Verification

Technical Specification - F Series